A one step synthesis of ethyl acetate from a feed mixture of ethene oxygen and water using a supported pd and silicotungstic acid catalyst was demonstrated.

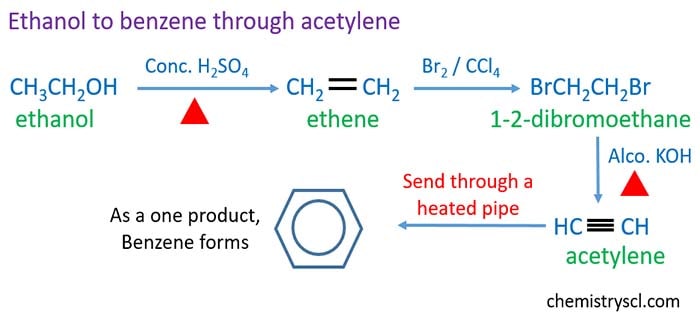

In one step ethyne can be obtained from ethanol.

Prior work obtained at only 0 58 v.

However this ketone can be generated from ethanol a renewable feedstock in one step.

Researchers have been redirecting their interest to the ethylene production process catalysts and reaction.

Acetone is an important solvent and widely used in the synthesis of drugs and polymers.

The process of ethanol to ethylene has broad development prospects.

Only 5 of the ethene is converted into ethanol at each pass through the reactor.

Both methane and ethane may be obtained by suitable one step reaction from.

One step electroreduction of co 2 to c2 products achieved using cu nanoparticles.

Phenol is a co product of this synthesis.

Currently acetone is mainly generated by the cumene process which employs benzene and propylene as fossil raw materials.

Compared with the process of petroleum to ethylene ethanol dehydration to ethylene is economically feasible.

Ethanol is manufactured by reacting ethene with steam.

Alkynes contain 2 pi bonds and only one sigma bond the 2 pi bonds can be broken so we add two molecules as ethyne contains two pi bonds beside one sigma bond it reacts by addition in two steps the triple bond is changed to double and then to single bond ethene reacts by addition in one step whereas ethyne reacts in two steps because.

How can ethyne be obtained from chloroform in one step chemistry haloalkanes and haloarenes.

10 current density for c2 products vs.

By removing the ethanol from the equilibrium mixture and recycling the ethene it is possible to achieve an overall 95 conversion.

This article is an up to date review of the literature available on the subject of ethanol to ethylene.

Morphology rather than oxidation levels of catalysts affects product distribution.

At about 180 c and 25 ethene conversion ethyl acetate could be produced with up to 46 selectivity together with 34 acetic acid and ethanol that could be recycled.

This work reviews a novel one step synthesis of cao zno catalytic particles suitable for biodiesel production.

They can be separated from the product and reused.

High performance when using a gde with rough catalyst in alkaline electrolyte.