Cleanrooms are designed to maintain extremely low levels of particulates such as dust airborne organisms or vaporized particles.

Iso cleanroom levels.

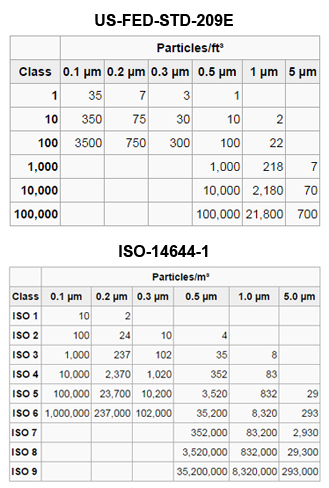

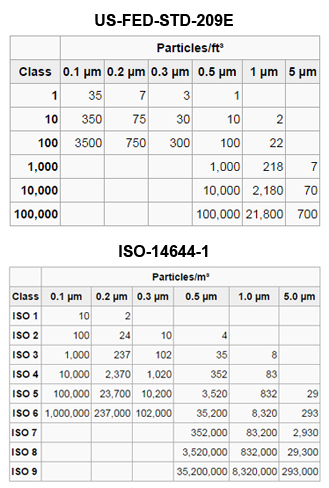

The particles range in size from 1 5 microns µm.

Classification of air cleanliness.

A cleanroom or clean room is a facility ordinarily utilized as a part of specialized industrial production or scientific research including the manufacture of pharmaceutical items integrated circuits crt lcd oled and microled displays.

A cleanroom must have less than 35 200 000 particles 0 5 micron per cubic meter and 20 hepa filtered air changes per hour.

Methods for evaluating and measuring cleanrooms and associated controlled environments.

Iso 8 is the least clean cleanroom classification.

In the uk british standard 5295 is used to classify cleanrooms.

In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock.

As an example iso 8 cleanrooms also known as class 100 000 cleanrooms can be modular or soft walled and have a maximum particle count of 100 000 particles 0 5 um per cubic foot of interior air.

Clean room classifications are based on an eight class rating system with an iso class 1 cleanroom being rated the most particle free and iso class 8 allowing the most particles.

Iso 14644 1 and older standard fs 209e determine class by the concentration levels of particles.

Cleanroom design and construction.

Terms definitions and units.

Iso 6 cleanroom class 1 000 in theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image.

The cleanroom classification standards fs 209e and iso 14644 1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area.

Cleanroom testing for compliance.

The lower the iso class the more stringent the requirements for keeping particles and contamination to the acceptable levels of the room class.

It also prescribes the standard method of testing as well as the procedure for determining the concentration of airborne particles.

When considering a certain iso classification of cleanroom it is critically important to ensure that your operation s needs align with the scope of the iso level you select.

What exactly is cleanroom classification.

This part of iso 14644 assigns iso classification levels to be used for the specification of air cleanliness in cleanrooms and associated controlled environments.

By comparison a typical office space would be 5 10 times more dirty.